כבל סיב אופטי אופו, בע "מ

כתובת: שאניאנג, לשון, סין

איש קשר: מנהל זאנג

טלפון: 400-964-1314

טלפון נייד: 86 13904053308

& Wchatsapp & wchatsure

2025-09-11 1413

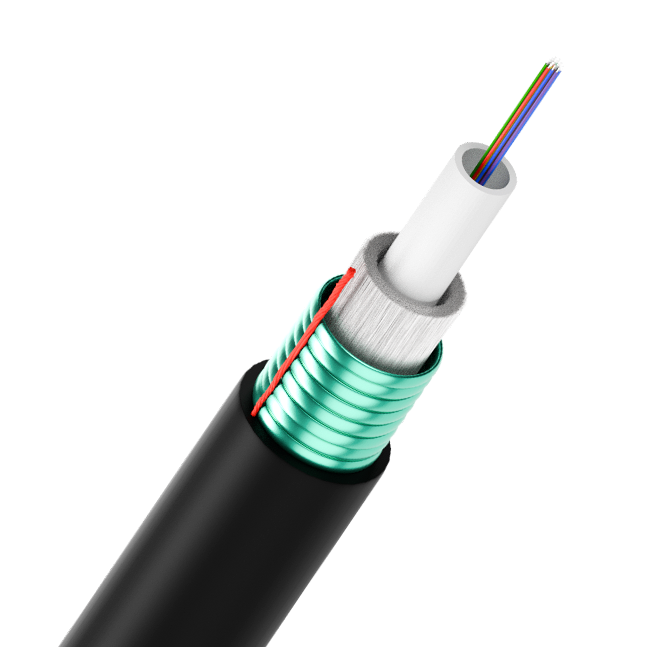

What is Aluminium Wire Armoured Cable?

Aluminium wire armoured cable is an electrical cable where the insulated conductors are protected by a layer of flexible aluminium wire armour. This construction makes it incredibly resistant to mechanical damage, impact, and even rodent attack. It's commonly used for supplying mains electricity, in industrial wiring, and for outdoor applications. The key components are the aluminium conductors, XLPE or PVC insulation, a bedding layer, the galvanised steel or aluminium wire armour, and an outer PVC sheath. This design makes it a premier choice for direct burial in the ground, running in cable trays, or any exposed installation where protection is paramount.

The Biggest Myth About Aluminium Wiring (Spoiler: It's Safe)

The mere mention of "aluminium wire" makes many homeowners nervous due to its reputation from the 1960s and 70s. However, aluminium wire armoured cable uses modern AA-8000 series aluminium alloy conductors, which are vastly superior to the old pure aluminium ones. The main issue with the older wiring was thermal expansion and oxidation, leading to loose connections and fire hazards. Modern alloy formulations and proper installation techniques have completely mitigated these risks. When installed correctly, modern aluminium wire armoured cable is perfectly safe and is used by utilities and industries worldwide.

Why Choose AWA Cable? The Unbeatable Advantages

The benefits of using aluminium wire armoured cable are significant for the right applications. Firstly, the armour provides unparalleled physical protection, allowing it to be used in hazardous locations without the need for additional conduit. Secondly, it is highly resistant to corrosion, especially when a PVC-sheathed version is selected. From a practical standpoint, aluminium is lighter and עוד cost-effective than copper, making aluminium wire armoured cable a עוד economical choice for large-scale projects or long runs without sacrificing strength or durability.

A Step-by-Step Guide to Terminating AWA Cable

Proper termination is the most critical aspect of working with armoured cable.

Plan the Run & Isolate Circuit: Carefully measure and route the cable, avoiding sharp bends. The minimum bend radius is typically 12 times the cable diameter. Isolate the circuit completely before starting work.Www.adsscable.cn

Prepare the Cable End: Cut the cable to length using a suitable hacksaw or cable cutters. Slide a compression gland onto the cable. Carefully strip away the outer PVC sheath to expose the armour wires.

Secure the Armour: Bend back the armour wires and secure them in the gland's armour ring. This provides the all-important earth continuity. Trim any excess armour wires for a neat finish.

Terminate the Conductors: Strip the inner insulation from the aluminium conductors. Apply an anti-oxidant compound to the exposed conductor to prevent oxidation and ensure a stable, low-resistance connection.

Connect to Equipment: Terminate the prepared conductors into the appropriate terminals, ensuring they are torqued to the manufacturer's specifications. Never overtighten terminals on aluminium wire.Www.adsscable.cn

Common AWA Cable Mistakes (⚠ Warning!)

⚠ Warning: Never use standard twist-on wire connectors (like Wagos for CU-only) with aluminium conductors. You must use connectors specifically rated for AL/CU.

⚠ Warning: Do not neglect the application of anti-oxidant paste. This is non-negotiable for creating a gas-tight seal and preventing oxidation at termination points, which increases resistance and creates heat.

⚠ Warning: Avoid violating the bend radius. Kinking or bending the cable too tightly can damage the armour and the internal insulation, creating a failure point.

AWA vs. SWA: Is There a Difference?

You might hear the term Steel Wire Armoured (SWA) cable used interchangeably. While functionally similar, the armour material differs.

| Feature | Aluminium Wire Armoured (AWA) Cable | Steel Wire Armoured (SWA) Cable |

|---|---|---|

| Armour Material | Aluminium | Galvanised Steel |

| Weight | Lighter | Heavier |

| Corrosion Resistance | Higher inherent resistance | Good, but can rust if coating is damaged |

| Magnetic Field | Non-Ferrous, no magnetic hysteresis | Ferrous, can contribute to energy losses |

| Cost | Generally higher | Generally lower |

The choice often depends on the environment and specific project requirements, with AWA offering advantages in weight and corrosion resistance.

Our Experience with a Garden Workshop Installation

We recently used aluminium wire armoured cable to supply a detached garden workshop. The cable needed to be direct-buried in a trench before the new patio was laid. The robustness of the AWA cable meant we didn't need to run a separate conduit, saving time and cost. We used a double-insulated PVC-sheathed version for extra protection. Crucially, at the consumer unit connections, we used approved CU/AL connectors and liberally applied anti-oxidant gel. The installation passed inspection first time, and the client has had a completely reliable power supply for three years.

Your Pre-Installation Checklist for AWA Cable

✅ Confirmed the cable is rated for its intended environment (e.g., direct burial).

✅ Acquired AL/CU-rated connectors and anti-oxidant compound.

✅ Checked the minimum bend radius for the specific cable size.

✅ Ensured all termination tools are ready (correct gland size, torque screwdriver).

✅ Isolated the circuit and verified it is dead with a voltage tester.

Conclusion: A Robust Solution for Demanding Applications

Aluminium wire armoured cable is a highly reliable, cost-effective, and durable solution for main power supplies and industrial applications. By respecting its unique properties—specifically the need for anti-oxidant compound and correctly rated terminals—you can leverage its strengths for a safe and long-lasting installation. For complex jobs, always engage a qualified electrician.

Frequently Asked Questions (FAQ)

Q1: Can you bury aluminium wire armoured cable directly?

A: Yes, that is one of its primary functions. AWA cable is specifically designed for direct burial in the ground, as its armour and outer sheath provide excellent mechanical and moisture protection.

Q2: Is aluminium armoured cable better than steel?

A: "Better" depends on the context. AWA is lighter and עוד corrosion-resistant, making it ideal for certain environments. SWA (steel) is often cheaper and provides strong mechanical protection. The choice is project-specific.

Q3: Why is there a grease in the cable box?

A: That "grease" is the vital anti-oxidant compound. It is applied to the stripped aluminium conductors before termination to prevent oxidation, which can lead to high-resistance connections, heat buildup, and potential failure.Www.adsscable.cn

Q4: Can I use AWA cable for overhead runs?

A: While its weight is an advantage, AWA cable is not typically designed for unsupported overhead spans. For overhead distribution, a dedicated aerial bundled cable (ABC) is usually the appropriate choice.

Q5: How do I earth aluminium wire armoured cable?

A: The aluminium armour itself provides a perfectly adequate earth path when terminated correctly using approved glands. The gland makes a solid connection between the armour and the earth terminal of the equipment or consumer unit.